Trump Tariffs & MAGA Manufacturing Myths: Can Factory Jobs Really Return to the U.S.?

Unless the manufacturing jobs are in mission-critical domestic industries - reindustrializing to satisfy populist yearnings is low IQ.

We all know Trump pushed a sweeping series of tariffs (some as high as 25%) on virtually all imported goods entering the United States.

Marketed as “Liberation Day Tariffs” (April 2025), these measures allegedly aim to break the country’s reliance on foreign suppliers and “bring back” American manufacturing jobs. (More info: Trump Tariff Formula Analysis).

Predictably, right-wing influencers hopped on board… “bring back manufacturing” and MAGA! Trump knows what he’s doing!

This led to the creation of some pretty hilarious AI-generated memes of MAGA hat kids working in textile factories, JD Vance sewing Nike logos on shoes, and Lutnick assembling iPhones — from those against Trump’s vision.

The right-wing “MAGA” party allegedly wants to retool the entire global economic order with Trump tariffs while increasing domestic manufacturing jobs to reindustrialize the U.S.

Fox News claims it’ll make America more “manly” and help “left-out young men” who can’t get jobs in the modern labor environment of 2025.

Trump’s rhetoric promises: new factories, good wages for working-class Americans, and independence from foreign supply chains.

Yet the reality around U.S. manufacturing suggests these tariffs are far more likely to undermine American competitiveness than restore it — especially given the administration’s contradictory actions/statements on human labor vs. automation and the lack of readiness in robotics to offset high labor costs.

Alleged Goals…

Revive the U.S. Factory Floor: White House officials promised a resurgence of traditional, manual-labor manufacturing roles, primarily pitched to the “forgotten men” who had lost stable factory jobs since the 1980s.

Economic Self-Sufficiency: In the face of geopolitical tensions, tariffs were framed as a strategic move to reduce U.S. vulnerability to global supply chains, particularly from China.

“Make America Great Again” via Industry: Politically, “retooling” was sold as a patriotic mission—an economic cornerstone to boost working-class wages and restore pride in domestic production.

Central Question

Does this push for labor-heavy “reindustrialization,” propelled by tariffs, make sense in a modern, high-wage economy?

Or put differently:

Have policymakers clung to a 1970s vision of manufacturing—mass assembly lines—when advanced economies thrive through automation, lean processes, and higher-value sectors?

Contradictions

There are several inconsistencies that undermine the tariff-based strategy.

A Skills Mismatch, Not a Lack of Jobs: Over 480,000 unfilled U.S. manufacturing positions already exist—requiring specialized skills many workers don’t have or don’t want to acquire.

Automation vs. Manual Labor: The administration simultaneously touts “unstoppable AI and robotics” while protecting union-heavy manual operations.

High-Wage Economy vs. Low Productivity: Trying to ramp up labor-intensive factories in a high-cost nation typically leads to either permanent subsidies (“MAGA socialism”) or uncompetitive pricing.

Note: No matter the actions taken by Trump, MAGA mind virus hordes will support Trump enthusiastically. First he’s just negotiating fair trade terms. Oh no he’s actually bringing back manufacturing jobs and won’t settle on trade terms! Which is it? He’s doing both! What if he doesn’t? Won’t you be mad if you don’t get your manufacturing jobs back? These people are like eternal fish with a hook stuck in their mouths being jerked in every direction at the whims of fisherman Trump to support the “current right-wing thing.”

Related: King Trump & the MAGA Mind Virus Tariffs: Economic Delusions of Grandeur

I.) The Core Fallacy: More Factory Jobs = A Stronger Manufacturing Sector

One of the dumbest myths in right-wing populist circles is that “bringing back factory jobs” from overseas will revive U.S. manufacturing.

Bustling assembly lines filled with hardworking Americans might fuel some nostalgia or historical fantasies, but this doesn’t reflect how modern manufacturing actually works.

Advanced economies like the U.S. thrive on automation, not manpower.

Success comes from producing more with fewer workers, thanks to robotics, software, AI, and capital-efficient machinery.

All factories of the future — whether in Germany, Japan, or China’s more advanced sectors — will use skilled engineers and precision systems, not labor-intensive processes.

FYI… eventually they’ll be entirely robotic… high IQ robots will fix & upgrade the robots. No you won’t need to fix the robots. I guess you can watch if you want.

America isn’t falling behind in manufacturing… it has shifted toward higher-value, capital-intensive, and innovation-driven sectors.

But populist political rhetoric still clings to and/or romanticizes a 1970s labor model, while the rest of the industrial world has embraced a 2030s vision: automation, specialization, and lean systems.

Trump is secretly going to automate? Ok I’m convinced now… just like he automated all U.S. ports — right? (Reality check: Trump gave the dockworkers a fat pay increase for NOT automating… U.S. has some of the least efficient ports globally. Retardio.)

II.) Decades of Decline: The Myth of the Manufacturing Comeback

The idea that manufacturing jobs "left" because of bad trade deals or poor leadership is one of the most persistent misconceptions in U.S. economic discourse.

The decline of manufacturing employment is neither recent nor uniquely American — it was a major structural global shift, driven by productivity gains, sectoral evolution, and strategic specialization.

From the 1940s to the late 1970s, manufacturing made up over 25% of the U.S. workforce.

Yet by 2023, that share had dropped below 10%… but this wasn’t the result of a singular policy failure.

The trend began well before NAFTA (1994) or China’s entry into the WTO (2001). And it didn’t just happen in the U.S.

The Global Pattern

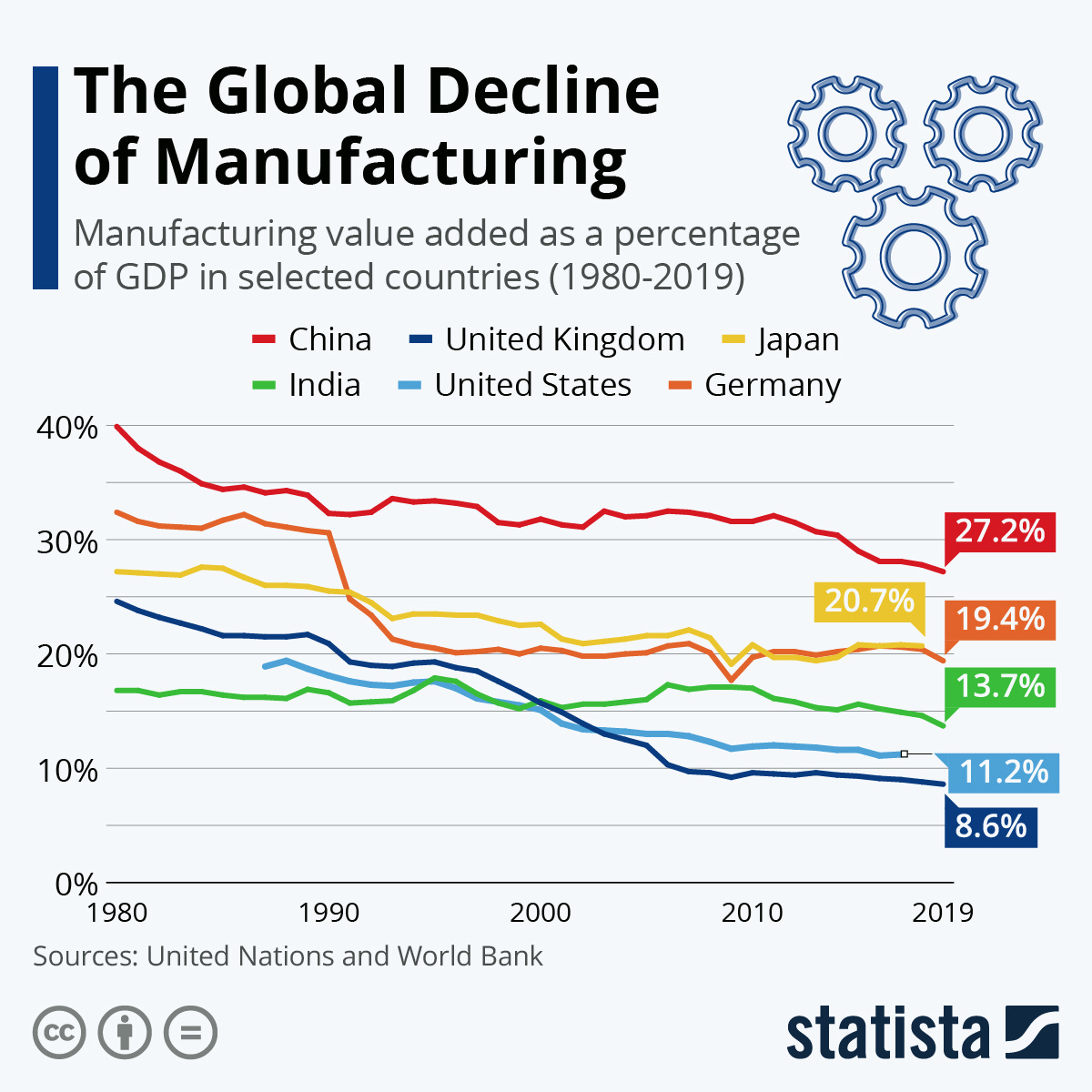

What happened in the U.S. also happened across the developed world.

According to UN and World Bank data, manufacturing’s share of GDP and employment has declined across all high-income nations, including Germany, Japan, and South Korea.

Even Germany, the gold standard of industrial manufacturing, saw manufacturing employment fall from ~24% in 2000 to under 19% by 2022.

Across the board, industrial jobs have become a smaller fraction of the workforce, not because output fell, but because machines got better, supply chains got smarter, and economies moved up the value chain.

The U.S. isn’t “falling behind.”

In fact, it’s done what advanced economies are supposed to do…

Specialize in high-margin production, R&D, and design

Outsource lower-value tasks that don't require proximity or advanced capital

Invest in productivity over headcount

In many cases, what we lost in raw job numbers, we gained in output per worker, technological capability, and sectoral diversification.

But this is where the policy disconnect begins. Politicians still speak of manufacturing as though it’s 1975 — focusing on headcount rather than throughput. As if the problem is a shortage of hands, rather than a shortage of strategic vision.

Reality: The real risk isn’t that we lost manufacturing jobs. It’s that we’re now trying to revive them using outdated assumptions about labor, costs, and global competition.

III.) The Reversal: More Hiring, Less Output Per Worker

Historically, U.S. manufacturing success has been defined by rising productivity and falling headcounts.

Starting in the late 20th century, automation, lean manufacturing, and capital investment enabled firms to produce more with fewer workers.

Between 1987 and 2007, manufacturing labor productivity grew at an average annual rate of 3.4%, even as total manufacturing employment steadily declined.

That paradigm has now fractured.

In recent years (especially since 2020) manufacturing employment has increased, while productivity has stagnated or declined.

This is not a temporary fluctuation. It reflects a structural shift with significant consequences.

Divergence Between Labor Input & Output

Just look at the graph below from the Tax Foundation… ~2010 manufacturing productivity spiked and manufacturing employment dropped significantly.

Then a sideways chop… followed by a spike again in 2020 but not much divergence.

Decades of productivity-driven output growth have been disrupted. Adding labor without improving output per worker signals a breakdown in industrial efficiency.

In a high-wage economy like the United States, this leads directly to rising unit costs, lower margins, and declining competitiveness.

And the numbers are even more revealing.

From 2000 to 2007, U.S. manufacturing still pulled its weight… manufacturing value-added rose 25.9%, even outpacing total GDP growth over that span.

But from 2007 to 2023, manufacturing value-added grew just 11%, while the broader economy expanded 33.5%. (Bureau of Economic Analysis)

The trend is clear: even when we keep manufacturing domestic, its economic contribution is shrinking. Throwing more labor at a structurally diminished sector isn’t revival—it’s misallocation.

Productivity Metrics: 1987-2007 vs. 2010-2022

A 2024 analysis from Liberty Street Economics (New York Fed) captures the severity of the shift.

Labor Productivity (BLS-defined)

1987–2007: +3.4%

2010–2022: –0.5%

Total Factor Productivity (TFP)

1987–2007: +1.4%

2010–2022: +0.1%

Revenue per Worker (Public Firms)

1987–2007: +3.5%

2010–2022: –1.3%

Leading Industries (e.g., Electronics)

1987–2007: +6.5%

2010–2022: –0.6%

Follower Industries

1987–2007: +1.9%

2010–2022: –0.6%

Labor productivity has turned negative. TFP — a measure of innovation and capital efficiency — has stagnated.

Even traditionally high-performing sectors like electronics and transportation equipment have experienced sustained slowdowns. No part of the sector is immune.

Policy Contradiction

This reversal should be alarming in light of federal attempts to reshore manufacturing using tariffs, subsidies, and industrial policy.

If firms are responding by adding labor without improving output, then the strategy isn’t rebuilding manufacturing competitiveness… but it would be bloating the cost base.

In a global environment where rivals operate with cheaper labor or superior automation, U.S. manufacturers can’t afford to compete by hiring more people. They must compete with higher efficiency (fewest people x automation).

Without productivity, the result is:

Higher unit labor costs

Reduced export competitiveness

Increased reliance on taxpayer subsidies

IV.) ~500,000 Vacant Manufacturing Jobs: “There Aren’t Enough Factory Jobs” (Myth)

One of the most common myths (especially from the populist right) is that “there aren’t enough manufacturing jobs” in the U.S.

We’re told that if only we slapped on more tariffs and built more factories, the working class would flood back into stable, high-paying industrial work.

That argument falls apart the moment you look at the data.

As of early 2025, there are 480,000+ unfilled manufacturing positions in the United States. These jobs exist. They’re posted. They’re ready.

And nobody wants them.

These aren’t the nostalgic “steel mill” jobs of the 1950s.

They’re roles in:

Precision machining

Mechatronics & industrial robotics

High-voltage welding

PLC systems and factory automation

CNC operation and advanced maintenance

They pay well (often above the national median) and yet they remain vacant.

Most do require a bit of specialized training (they aren’t all “low skilled manual labor”) — they’re semi-skilled (probably something the median American could do if they wanted.)

The Problem? Not Enough People Want to Work in Manufacturing and/or are Qualified

We aren’t only dealing with a skills mismatch in the U.S. for manufacturing… there’s often a preference mismatch.

Many Americans don’t want to pursue these roles, even if they pay well and offer security. But why?

These jobs often involve physical labor, nonstandard shifts, and geographic relocation to unappealing industrial zones.

They rarely offer the kind of flexibility today’s workforce increasingly values—remote options, creative control, or advancement into management.

Cultural and educational messaging for decades has told students: “Go to college, get a desk job, avoid the trades.”

The result? Even as reshoring incentives flood capital into new facilities, there’s a growing labor vacuum in the very sector politicians claim we need to revive.

Tariffs and subsidies don’t fix that. You won’t necessarily legislate career aspirations.

What the Right gets wrong…

When politicians on the right claim, “We need to bring back American manufacturing jobs,” they’re skipping over what’s right in front of their faces: The jobs are already here. People aren’t taking them.

There is no army of idle, able-bodied Americans knocking on factory doors and being turned away.

If anything, the factories are the ones doing the knocking… looking for talent that no longer exists at scale.

This isn’t the 1950s. The labor market has changed, preferences have changed, and the nature of work has changed.

Rebuilding a labor-heavy industrial base in 2025 won’t restore economic stability. It’ll likely create subsidized facilities with chronic understaffing.

Populist right-wing politicians are chasing a workforce that doesn’t exist anymore.

The manufacturing jobs we “lost” haven’t disappeared… they’ve become more advanced and much of the workforce has moved onto other sectors.

Any strategy to “bring them back” without fundamentally rethinking education, culture, immigration, and automation is delusional.

V.) The Cost Trap of Labor-Heavy Retooling

The push to “bring back” U.S. manufacturing often comes with a dangerous assumption: that we can restore labor-intensive factory work as a cornerstone of national strength.

In a high-wage, capital-intensive economy like the United States, that model is outdated and ultimately economically self-defeating.

High Wages Require High Output

American workers are expensive.

Once you factor in wages, benefits, compliance, insurance, and regulation, the total cost per factory worker in the U.S. can be 5x to 10x higher than in countries like Vietnam, India, or Mexico.

That cost can only be justified if each worker produces far more—typically through advanced capital investment and automation.

Without that output gain, the math breaks down. Unit costs rise. Margins shrink. Global competitiveness vanishes.

You don’t need a PhD in economics to understand the equation:

High wages combined with high output (via automation) equals a viable model.

High wages combined with low output (via labor-intensive methods) equals a failed one.

The Strategic Dilemma: 2 Paths, No Easy Answers

U.S. industrial policy now faces a choice it refuses to acknowledge:

Automate the factories. This ensures global competitiveness and output efficiency. But it creates far fewer jobs than politicians promise. It also requires heavy upfront capital and multi-year implementation timelines; significant latency.

Staff factories with human labor. This satisfies the nostalgic political narrative of "bringing jobs back"—but it sacrifices cost-efficiency and guarantees strategic defeat. No amount of tariffs will make $30/hour factory labor competitive with fully automated production in China or Germany.

Essentially, it’s this:

If you automate, you won’t have as many jobs as you think.

If you don’t, you lose to China—on cost, scale, and innovation.

And while you're retooling (slowly, bureaucratically) China is accelerating ahead, investing in AI, vertical integration, and industrial scaling at a pace U.S. policy can’t match.

There is no path that leads to cheap labor, high wages, robust job growth, and global dominance all at once. Something has to give.

Old-School Factories are a Strategic Liability

The nostalgic image of industrial rebirth—factory lots full of cars, workers punching clocks, neighborhoods anchored by smokestacks—may have symbolic value. Economically, it's a liability.

Labor-heavy reindustrialization delivers:

Slower throughput

Higher per-unit costs

More errors and downtime

Weaker scalability

Structural dependence on government support

Meanwhile, high-performing manufacturing economies like Germany, South Korea, and Japan are investing in:

Industrial robotics

Precision supply chains

Digitally integrated factories

Workforce automation, not expansion

Trying to replicate a mid-20th-century labor model in a 21st-century industrial landscape clearly won’t work.

Retooling w/o Automation is Subsidized Inefficiency

Despite political enthusiasm, there is no large-scale national effort to automate at scale.

There is no industrial AI deployment strategy… and reconfiguring the entire U.S. will take time (manufacturing plants won’t pop up overnight and start churning out fleets of drones.)

What we do have are:

Tariffs

Sporadic tax credits

Groundbreakings without skilled labor pipelines

Vague slogans about “Made in America”

This seems like a completely incoherent gameplan that will lead to government subsidized inefficiency to satisfy populist fantasies.

The “MAGA Socialism” Problem

The irony is stark: many of the same voices denouncing big government and “welfare” are now advocating state-subsidized factories that would not survive in a free market.

They demand protectionism, targeted tax breaks, and long-term government dependency—precisely the conditions they reject in every other policy area.

This isn’t free market economics.

Even with subsidies, labor-heavy retooling doesn’t fix anything. It just delays collapse.

Without productivity gains, U.S. manufacturing will not be competitive.

Without automation, high wages become a liability.

Without strategic clarity, any reindustrialization effort becomes an expensive, slow-moving attempt to rebuild a past that no longer works.

Right now we have zero strategic clarity from Trump and his MAGA henchmen.

VI.) Policy Contradictions: The Automation Double Standard

U.S. manufacturing policy talk today has been incoherent.

Political leaders on both sides of the aisle claim to support a revival of American industry, often using terms like “human jobs,” “economic dignity,” or “rebuilding the middle class.”

On the right, Trump-era economic advisers have framed reindustrialization as a path to restore purpose and prosperity to young men “left out of the modern economy.”

But when you compare rhetoric with actual actions, the contradictions are glaring… suddenly they’re for advanced automation (higher skilled work)… this would do jack shit for the “left out” men (they don’t have the skills).

You might say Well if you gave them a chance they could do it…. and someone might reply They can do it right now… there are nearly half a million manufacturing job openings throughout the U.S.

Automation Talk… Anti-Automation Action?

One of the clearest examples: America’s ports. I’ve harped on this for a while.

If you advocate for “DOGE” (making the government more efficient) but are fine with the ports operating with a horse and buggy while the rest of the world is onto flying cars… you’re not a serious person.

The United States has some of the least automated ports in the developed world. Major terminals in places like Los Angeles and Long Beach still rely heavily on human-operated equipment, paper manifests, and legacy logistics infrastructure.

Trump’s team repeatedly promoted themes of American productivity and infrastructure revitalization. But when the moment came to act (specifically, to support automation of U.S. ports) the administration sided with longshoreman unions over modernization.

The result? The U.S. remains far behind Asian and European ports in throughput efficiency, cost per container, and digital logistics integration.

We left billions in economic potential on the table — all to protect a few thousand high-paying union jobs from inevitable technological disruption.

If the priority was truly to make American industry globally competitive, port automation would have been a top priority. Instead, it was inconvenient with populists so it remained ignored.

“Bring Back the Jobs” — Will they Be for Avg. Americans?

While Trump-world publicly promises a return to factory floors for the working class, their own policies, statements, and appointments tell a very different story.

Howard Lutnick, now Commerce Secretary under Trump, has stated that the future of American manufacturing will be highly automated — run by robotics engineers, system technicians, and AI-trained operators. (Axios, 2025)

He envisions factories leveraging automation to replace offshore labor, even suggesting that products like iPhones could be assembled in the U.S. using robotic systems.

Even Peter Navarro (or maybe we should say Ron Vera? IYKYK) one of the loudest voices blaming trade deals for U.S. job losses, has shifted toward a capital-intensive vision of reshoring.

He explicitly cites Germany as the model — an advanced manufacturing economy defined not by labor-intensive work, but by export-driven, high-tech, automated industry.

Here’s the contradiction:

You’re selling dislocated, working-class Americans the fantasy of stable, blue-collar factory jobs… But you’re building an economy that doesn’t include them.

You can’t simultaneously: (A) Call for a global manufacturing resurgence & (B) resist automation (hiring “left behind” men).

Trump’s staff has said they are for automation… but their actions aren’t aligned with this talking point (if they were they’d have automated the ports and bought out the longshoremen).

The only way to compete in modern manufacturing is with:

High-throughput robotics

Smart production lines

Autonomous logistics systems

Precision machining at speed and scale

Subsidize, Then Stall?

Even the rhetoric around industrial subsidies follows this contradiction.

Biden’s CHIPS Act and Inflation Reduction Act (IRA) are flawed, bloated, and laced with ideological baggage — but better than nothing.

Union labor mandates

DEI strings

Domestic content requirements that limit flexibility

Trump is right to criticize the woke baggage. But what does he propose instead? Tariffs. This increases costs, strains international relationships, and often has limited success in reshoring industries — plus creates inefficiency (takes time to reshore).

He’s called the CHIPS Act a “horrible, horrible thing” and has promised to repeal it with no replacement.

Even as global competition for semiconductor sovereignty heats up, Trump is now pledging to gut the only programs currently building U.S. capacity in favor of his tariff strategy… likely a worse option.

And let’s not forget… during Trump’s first term:

Bonus depreciation for capital investment was allowed to phase out: Which discouraged domestic investment, penalized capital-intensive industries, and contradicts the goal of making U.S. the global hub of high-end manufacturing.

Immigration policy was tightened: Reducing access to engineering and skilled manufacturing labor.

Automation was ignored entirely: Trump favored “real human” workers.

There was endless talk of reshoring, but it was mostly just optics that Trump could market as Making America Great Again.

Now, just as domestic production in critical industries begins to scale up — chip fabs, battery plants, defense suppliers — Trump wants to pull the plug.

If he dislikes the Chips Act at least propose something that’s better to accelerate advanced semiconductor tech… tariffs are a highly-questionable strategy and will likely slow progress.

The Common Theme: Optics > Outcomes

Jobs are promised that won’t scale. Factories are announced without workforce plans. Ports remain outdated.

Semiconductor sovereignty is invoked while the CHIPS Act — flawed but directionally important — is targeted for repeal, with no alternative framework proposed.

To be fair, Trump’s admin insists there’s a plan.

Howard Lutnick has described a future of highly automated domestic production.

Peter Navarro points to Germany as a model — a capital-intensive, export-driven manufacturing economy.

Supporters argue that Americans can fill these roles, that training pipelines will emerge, that R&D and engineering investment will follow once tariffs and subsidies reshape incentives.

Maybe that happens.

Right now, there is no coherent plan. No proposed strategy for building up factories, scaling technical labor, integrating automation, or managing the transition between political promise and industrial execution.

What we have instead is a scattershot of talking points — slogans about tariffs, reshoring iPhone factories, advanced automation comments, and vague aspirations for American-made everything.

It’s not that the future they describe is entirely impossible. It’s that no one from the Trump admin has put forth an actual plan.

Meanwhile, the rhetoric continues selling factory jobs for “left behind Americans” to voters — while quietly laying the groundwork for lean, robotic production facilities designed for a labor force that doesn’t exist yet and isn't being meaningfully prepared.

America Needs a Reality Check: Strategic High-Efficiency Manufacturing is Good.

We’ve heard the narrative: tariffs will bring back jobs, restore dignity to working-class men, and reindustrialize America.

Trump’s 2025 “Liberation Day” tariffs repackage that same old pitch — now turbocharged with culture war buzzwords and patriotic branding.

Right-wing media promises a resurgence of “manly” factory labor. The MAGA base is fully aboard the Trump Train.

I’ll reiterate: the fantasy of rebuilding America with legions of factory workers ignores decades of reality. Economic gravity and technological acceleration will not bend to populist fantasies.

The data shows manufacturing productivity stagnating where labor is simply added. The global shift towards automation is relentless and accelerating.

The U.S. workforce itself has evolved – nearly half a million existing manufacturing jobs sit unfilled because the skills or desire aren't there.

And the broader truth is even harder to swallow: no advanced economy is bringing back mass employment in manufacturing.

They’re automating, digitizing, integrating AI, and streamlining headcount. The more serious the industrial policy, the fewer workers required to generate high output.

Where would the U.S. benefit from more manufacturing?

Semiconductors

Energy systems

Rare earths & defense components

Aerospace infrastructure

Grid & power resilience

These should be built up domestically to ensure supply chain sovereignty, crisis resilience, and geopolitical autonomy.

But these will not create zillions of new jobs… think: automation, robots, AI, etc.

The Real Choice

If America does it right, there won't be more traditional manufacturing jobs.

There will be vastly superior factories, smarter systems, fewer people, higher-value work, and global technological dominance.

Perhaps eventually the U.S. will achieve efficiency/productivity thresholds that warrant radical ideas like UBI. (Don’t Count Your AI Chickens Before they Hatch: Risks of Premature UBI)

That should be the direction the U.S. is headed… not a neo-Luddite retreat towards a past that’s already DOA.

What’s my strategy to fix the U.S. economy and pay down the insane debt? I outline it here: Trump Tariffs & MAGA Socialism vs. My Strategy (ASAP Protocol). I think it’s possible to fix the U.S. without current Trump tariffs or bringing MAGA merch sweatshops back from Cambodia.